Search

Premium Solutions

Expanding your CNC machine tool’s capabilities

In addition to our Intelligent Technologies, we offer a whole separate subset of Premium Solutions to take your machining capabilities to the next level. Advanced technologies like Turn-Cut, Threading suite or Hyper-Surface offer key benefits for the industry and are specifically designed to enable the most accurate, complete, and productive machining processes.

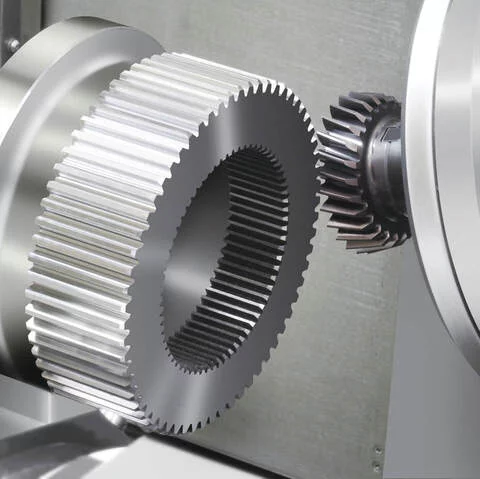

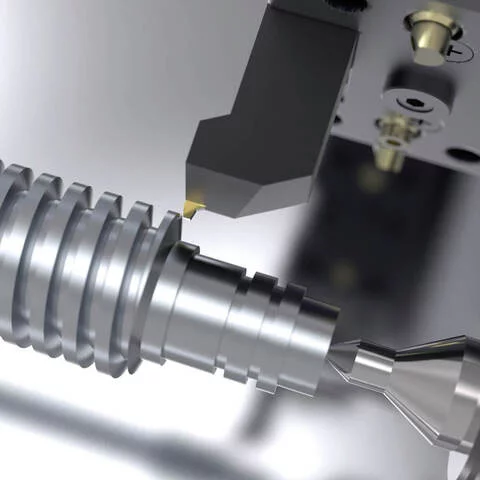

Gear Machining Package

Easy multitasking for gears

Our affordable Gear Machining Package is the perfect combination of hardware and software and delivers a single multitasking machine capable of high-accuracy gear cutting that previously required expensive dedicated machines. Simply enter the tool types, gear specs, and cutting conditions for seamless machining, whether you are skiving or hobbing. The package can be used without any prior programming knowledge.

Benefits

- User-friendly dialogue, easy and vastly shorter programming

- Shortened overall processing time

- Synchronicity of multiple spindles

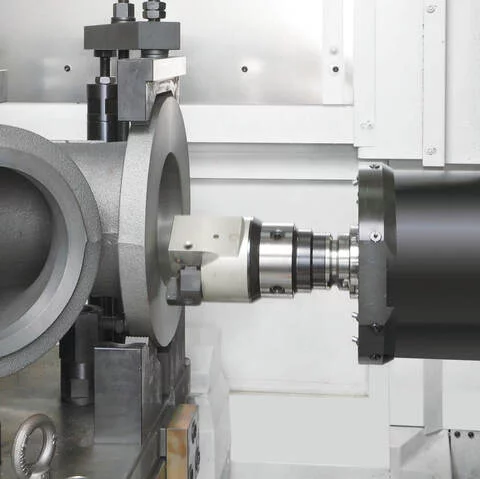

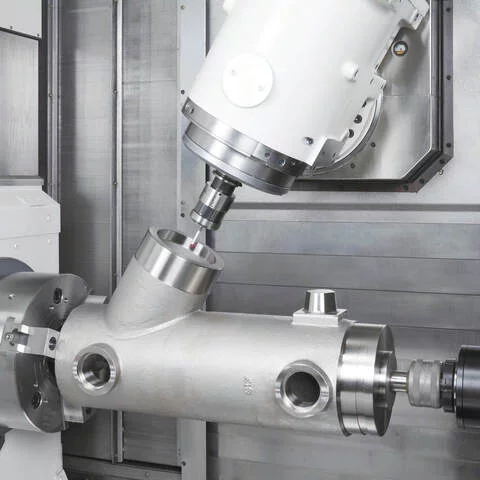

Turn-Cut

Turning on Machining Centres

Designed for applications that would traditionally require a CNC lathe to turn a feature, Turn-Cut eliminates the need to purchase such special purpose machines, along with any additional tooling, fixtures or add-on components. In many cases, a part’s size, shape or weight makes it impossible to set up on a lathe anyway; but with Turn-Cut, large, awkwardly shaped and unbalanced parts remain stationary as a new tool path is created. Since Turn-Cut synchronises the X and Y circular motion with the spindle angle, the tool edge maintains that newly programmed path for the duration of the job.

Benefits

- Optimised process capabilities without specialised tooling, attachments or secondary machines

- Consistent and accurate machining performance even in applications that do not require Turn-Cut capability

- Reduced setup times

Flat-Tool Grooving

Airtight Seal Grooving

Our Flat-Tool Grooving function effectively improves the surface roughness of seal grooves. Cutting grooves with end mills often leaves the curves not properly sealed-off. End mill cutter marks at the groove bottom reduce airtightness and thus requiring hand finishing. By finishing the groove bottom with a flat tool you will achieve a machined surface where air does not leak easily. When grooving a complicated curve, the spindle phase is precisely synchronised with the cutting edge motion to perform highly accurate grooving.

Benefits

- High sealability without hand finishing

- Complex seal groove curves cut with flat tools

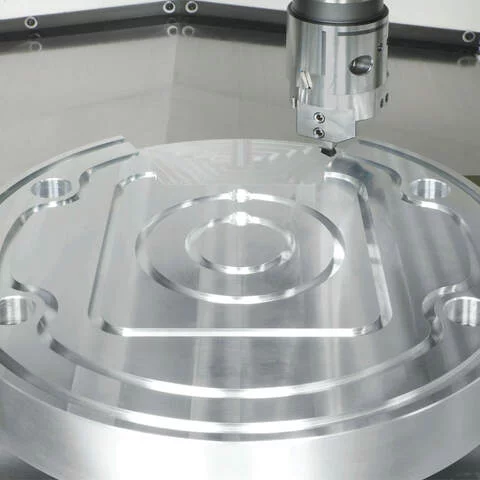

Hyper-Surface

Easy and improved Die&Mould surface quality

Our Hyper-Surface feature detects CAM-output machining data disturbances and variations, which result in scratches on the surfaces. It automatically makes corrections on the Okuma control to improve the surface quality without modifying the machining data while maintaining the required shape accuracy. This not only eliminates the time usually required for hand finishing, but also reduces scratches and uneven edges.

Benefits

- Corrects variations in command position and feed rate

- Improves machined surface quality and eliminates time required for hand finishing

- Aligns adjacent cutter paths and reduces scratches and uneven edges

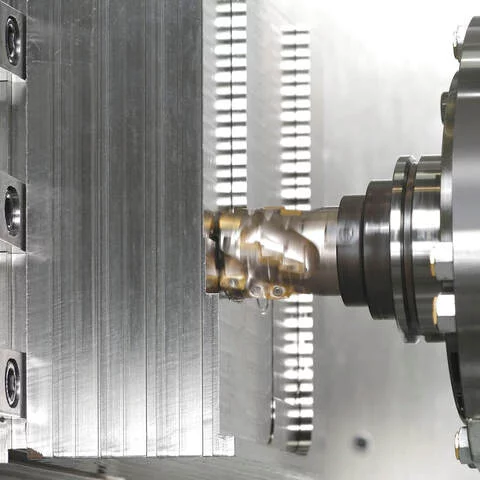

Dynamic Tool Load Control

Improved productivity of difficult-to-cut materials

Dynamic Tool Load Control effectively suppresses chipping when using insert-tipped tools, achieving stable machining for difficult-to-cut materials. It compensates tool run-out by feed variation. The run-out, typical for insert-tipped tooling, is measured and a constant load for every insert is ensured.

Benefits

- Significantly extended tool life up to five times

- Stable machining of difficult-to-machine materials and reduced machining costs

- Shortened tool change and stop time

B-Axis Turning

Efficient curved-surface turning

Our B-Axis Turning feature provides efficient curved surface turning as X-, Z- and B-axes of a multitasking machine are simultaneously controlled. Therefore, jobs without tool changes allow curved surface applications. When cutting a curve, machining can always be done at the best tool angle to eliminate ridges and get a uniform quality.

Benefits

- Provides the best tool angle at any time

- Eliminates ridges and allows highest curved surface quality

- No tool change necessary

Auto Attachment Head Compensation

Easy rotational compensation for Double-Colums

The Auto Attachment Head Compensation is an easy way to automatically set head rotation compensation values. The settings can be done within 20 minutes and do not require special operator skills. By comparison with former measurement results, changes in machine geometry can easily be detected. Regular checking guarantees constant accuracy when working with the different attachments in different orientations.

The tool-tip position varies according to the large variety of attachment heads. The compensation values keep the tool-tip at the same position even with different attachment head types or rotation tilt.

Benefits

- Incredible time savings from hours of manually tuning to minutes of auto-tuning

- Improved work efficiency and improved accuracy

- High reliability independent of operator skills

NC Gage

Process-intensive 3D gauging for multitasking

Simple programming to measure the positional relationship between geometric tolerance and workpiece shape is automatically produced by intuitive teaching. 20 types of geometrical accuracy, such as hole position and flatness, can be measured on the machine and hence greatly reduce lead time. It is possible to store the gauging results as electronic data.

Benefits

- Intuitive “Teach-In method” to create measurement programs

- Easy setup and changing of parts

- Eliminates operator error and reduces scrap rate

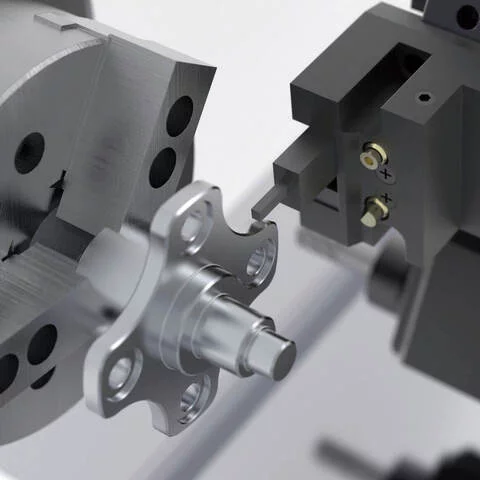

C-Axis Torque Limit

Easy and automatic phase matching

Here is how to get C-axis zero offsets: a stopper mounted on the turret contacts the cutting reference to read the torque fluctuations. The phase setting is easily done without any measuring devices. In case a workpiece has a keyway, both sides will be detected by reciprocating CW/CCW rotation to reference the C-axis to the centre position.

Benefits

- Eliminates operator- and fixture-related mounting errors and phase matching

- No need for inprocess gauging

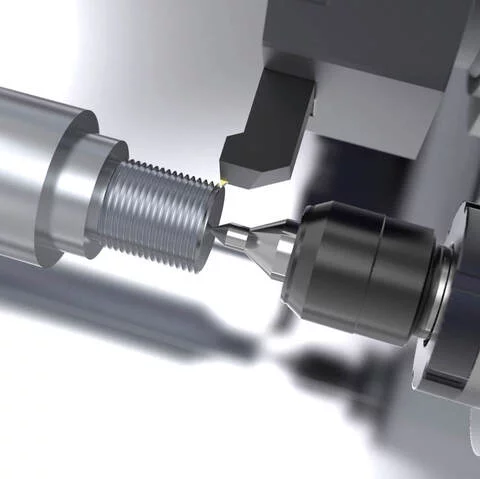

Variable Spindle Speed Threading

Changing conditions during threading while maintaining the thread pitch

With our Variable Spindle Speed Threading, changing the override during threading is possible to set best conditions, reduce pitch shift and avoid false geometries. When chatter occurs, the spindle speed can be lowered, then raised again when cutting conditions appear acceptable. The feed axis is perfectly synchronised, and thread pitch accuracy is maintained. Integrated cycles allow spindle speed variation while cutting in automatic mode and avoiding chatter build-up.

Benefits

- Optimises cutting conditions

- Allows changing spindle speed

- Provides constant thread pitch

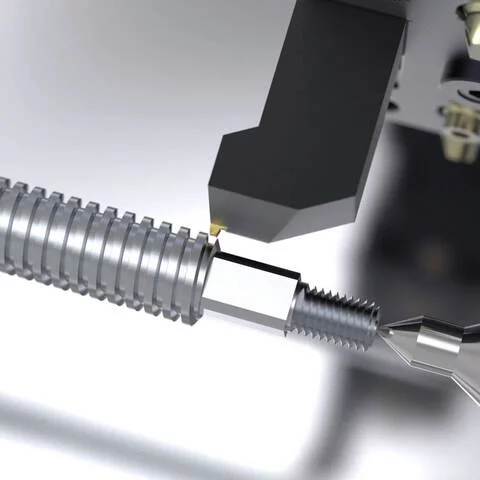

Variable Lead Threading

Easy threading of variable pitches with difficult programs

The Variable Lead Threading makes changing screw pitches easy. As with regular threading programs, giving the increase or decrease command enables variable pitch threading. Programming commands set the pitch change amount per pitch as needed.

Benefits

- Enables easy programming for variable pitch threading

- Simply increase or decrease the pitch

Thread Phase Matching

Recutting threads made easy

The Thread Phase Matching makes it simple to set the start position when it comes to recutting an existing thread. To avoid that phases do not match after a rethread or finishing, manually aligning the tool by pulse-handle move is all that is necessary - even after unchucking or threading on another machine.

Benefits

- Easy setting of start position

- Simple manual adjustment