Search

Automation

Sophisticated Factory Automation

In addition to smart machines and IoT-data processing, robotic automation is key for providing the capacity for unmanned production in state-of-the-art smart factories. We offer robot assisted set-ups, both turnkey and custom solutions employing industry-leading robotics from our renowned partners. Your local Okuma distributor will be happy to give you a call or visit your facility to discuss suitable automation solutions.

ARMROID

Next-Generation Robot System

The ARMROID system includes an articulated robot built inside the machine tool that performs many functions, including part loading/unloading, tool changing, workpiece support and high-pressure coolant flushing. ARMROID can be manned by an operator during the day shift and run unattended at night, to maximise all available resources. It is extremely easy to install, easy to program, and requires no third-party system integrator.

STANDROID

Next-Generation Robot System

The STANDROID system is an innovative, easy-to-setup robot package that offers higher productivity for any machine shop. From standard packages for minimal automation to comprehensive expansion packages – the available selections are designed to meet all kinds of production requirements. It is extremely easy to install, easy to program, and requires no third-party system integrator.

Pallet Pickers

Okuma MU-S600V in a two-unit set-up with

two ABB PalletPickers for loading and unloading.

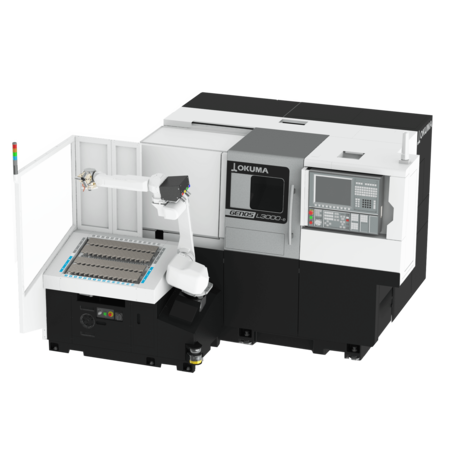

RoboJob Turn-Assist 200

Okuma GENOS L3000 with RoboJob Turn-Assist 200 for automated loading and unloading of small and medium-sized batches.

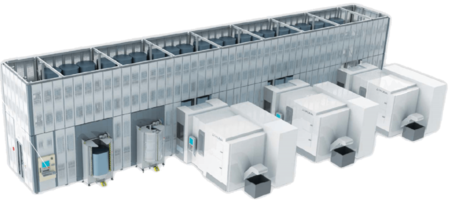

PALLETACE

Okuma PALLETACE is a standard FMS that can

utilise one or multiple Okuma machining centres.