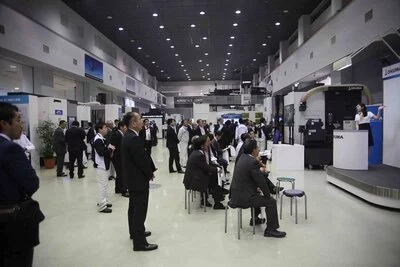

The Okuma Machine Fair (OMF) marks a biennial highlight for the manufacturing industry. From 23-26 May Okuma welcomed more than 8.000 guests at the Japanese headquarters in Oguchi. Our latest innovations not only garnered the interest of over 4.000 domestic companies, but also convinced 266 international companies to make the trip to Japan. Highlights included a tour through our newly completed Smart Factory Dream Site 2 and our latest product innovations, such as the LASER EX series of Super Multitasking Machines capable of turning, milling, laser hardening and additive manufacturing. Our sophisticated Smart Factory Solutions meanwhile presented new ways to take productivity and efficiency in an IoT environment to the next level.

This year's fair was particularly exciting as it coincided with Okuma’s 120th anniversary and the opening of the new fully-automated Dream Site 2 (DS2) parts factory. Even more advanced than Okuma's self-contained start-to-finish-factory DS1, DS2 eliminates manual handling of materials between different machine tools completely. Instead, Automatic Guided Vehicles (AGV) are used to considerably cut down time between machine set-ups.

Guided tours through the facility served to underline Okuma's smart-factory expertise, as it directly translates to the Smart Factory Solutions presented to customers at the fair. These advancements allow for total control of the entire planning and manufacturing process to enable 24/7 super high-mix, low volume production. Okuma's Factory Monitor enables visualisation of the entire plant, showing the status and position of every single machine in use. The applications accumulate and store data on machine runs, downtimes etc. so that continuous improvements can be made accordingly, making each run better than the one before.

These solutions as well as Okuma's Super Multitasking- and Smart Machines will make their European debut at this year's EMO in Hannover (18-23 September).